VIA Motors stands at the forefront of electric truck chassis development with its revolutionary VDRIVE™ skateboard architecture and VTRUX® portfolio of EV work trucks. We speak to executive members of the company to learn more about the electric drive technology changing the commercial fleet landscape.

INTRODUCTION

Commercial fleets, including last and mid mile delivery, is a crucial sector and the lifeblood of American logistics. According to the American Trucking Association (ATA), almost $900 billion is made in gross freight revenues from trucking, spanning long-haul interstate shipments to smaller-scale regional deliveries.

Within this mobility frontier, the incorporation of technological development is key to maintaining a foothold for commercial fleets across the US, be it advancements in navigation, fuel economy, comfort, performance, or renewable energy use.

VIA Motors (VIA) is a specialist in the field of electric vehicle (EV) advancement, engineering all-electric work trucks from the ground up, that are preferred by drivers and valued by fleets of all sizes. At the heart of the company dwells an established mission to deliver EVs with zero compromise. Adaptable tailored solutions, electrified cost efficiency, and a pledge to zero-emission sustainability coalesce, resulting in the basis of a business aimed at creating a more efficient and liveable world for all, one mile at a time.

THE WINNING COMBINATION AT VIA MOTORS

VIA’s story and success have always been defined by its people, industry expertise, and strong leadership. Chairman Bob Lutz was previously Vice Chairman of General Motors (GM), and a driver behind the Chevrolet Volt. Bob Purcell, CEO of VIA, previously led the General Motors Advanced Technology Vehicle Group and brought the GM EV1 to production that was released in the 1990s. This next led to the development of the skateboard chassis at GM in the late 1990s, debuted on the Chevrolet Triax concept vehicle introduced at the Tokyo Motor Show in 1999. The Triax was slated to be the second generation EV1 as a 2002 production program. Tesla CEO, Elon Musk, commented that GM “should have gone to EV2 and EV3.”

Frank Jenkins, Executive Director Sales and Marketing at VIA, has over 40 years of experience in the fleet business (including 28 years in GM’s Fleet and Commercial Division) and joined the EV space in its early stages with a specific focus on commercial light, medium, and heavy-duty segments.

Furthering this pool of expertise, Natalie Fitzpatrick, Architecture Chief Engineer and Program Manager at VIA, has led a 35-year career in product development with GM, thereafter joining Chevrolet and becoming heavily involved in the development of the Chevrolet Volt. Stemming from a lifelong passion in the field of electrification and engineering, Fitzpatrick has spent most of her career in the EV segment.

“VIA began in Utah’s Silicone Slopes – one of the top places in the country for tech innovation and start-ups,” introduces Purcell. “While our R&D facility is still located there, our headquarters in Auburn Hills is purposely located in the heart of the automotive capital. The result is that we get the best of both worlds here at VIA.

“It is a winning combination that allows us to stay at the forefront of EV tech and bring a vehicle to production in the right way,” Purcell continues.

“VIA is a full-scale original equipment manufacturer (OEM) designing and producing a portfolio of sustainable and cost-effective electric work trucks to transform the commercial fleet business,” outlines Jenkins. “We are backed by 12 years of experience perfecting electric drive technology, including software and algorithms, guided by an experienced board, chaired by auto legend and Chairman of VIA, Bob Lutz,” he says.

“We are staffed by incredibly talented and skilled veterans in the industry,” states Purcell. “VIA has the experience of an OEM and the agility of a start-up which makes us the partner of choice in the field; we make tools, not toys, delivering functional, reliable, durable, and cost-effective electric work trucks,” adds Purcell.

TRANSPORTING THE FUTURE

Moving ahead into the new year, VIA is recognizing a fundamental shift in the world’s automotive industry, especially when it comes to EVs in the commercial sector.

“Throughout history, we first had horses transporting goods, then the field developed to the use of combustion engine vehicles, and now the industry is moving to add electric motor-powered vehicles,” Purcell notes. “In fact, this notion of development is how VIA got its name ‘VIA Motors, by way of motors’. Electric drive makes economic and environmental sense, and it is exciting to be a part of it.”

For Purcell, there are three overarching trends that are shaping modern living, and by consequence, VIA’s goals: population growth, urbanization, and the rise in e-commerce. Each of these factors has resulted in increased congestion on roads and in neighborhoods, and as such, VIA is creating industry leading electric work trucks based on a skateboard architecture that will help transform the commercial fleet business. Electric drive technology has its place in the world, particularly today and especially for commercial fleets. The application of electric drives to commercial fleets provides a lower cost of operation and reduced environmental impact.

“It is projected that the world population is expected to eclipse 10 billion by 2060. We are also seeing that the number of megacities (cities with over 10 million inhabitants), is projected to rise. On top of all that, we are seeing an explosion in e-commerce. Society is increasingly shifting towards online shopping instead of brick-and-mortar stores, leading to a steeply increased demand for delivery vehicles in the world’s cities.

“A smart solution for these megatrends is the electric drive, providing clean, efficient, and cost-effective solutions. In light of this, our priorities include a rigorous product development process moving from prototype to production vehicles, the completion of our staffing and finalizing our strategic supply base, and lastly growing the customer base for selling cab chassis, vans, buses, and skateboards. VIA’s ramp-up of production is targeted in the second half of 2024, to deliver cost-effective sustainable mobility solutions.”

ELECTRIFYING THE US

According to Purcell, VIA is operating at the center of an ever-changing industry filled with development and opportunity.

“VIA’s approach to electric drive provides both sustainability and cost-effectiveness. With VIA, it’s not a trade-off as the company is driven to optimize both aspects as an essential enabler of electric propulsion adoption.”

VIA has found a significant level of interest from customers in the commercial segment, especially in the last-mile delivery industry.

“The combination of tax credits and eliminating fuel and reducing maintenance costs allow for great ROI (return on investment) on commercial EVs,” Jenkins says. “There are also regulations for commercial fleets to meet sustainable targets by 2030. We are working with customers on awareness and facilitation in this area, merging environmental needs with our business goals.”

INDUSTRY-LEADING TECHNOLOGY

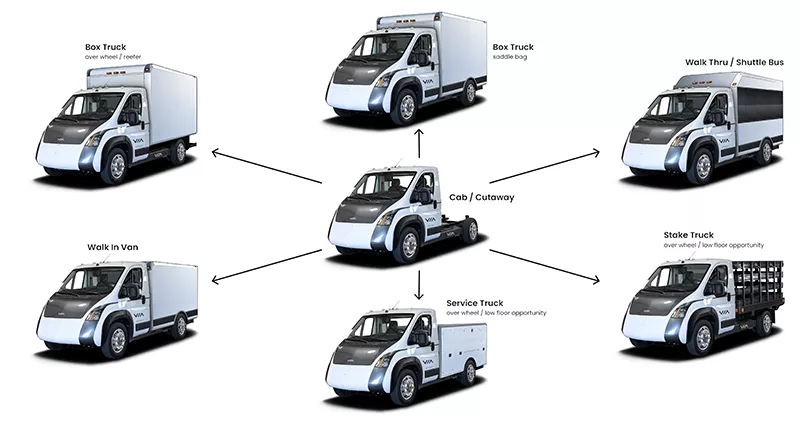

VIA is currently developing Class 2 through 5 electric commercial work trucks and buses. On top of the company’s VDRIVE™ skateboard architecture, VIA also offers VTRUX®, a flexible electric work truck platform, with chassis cab and cutaways and can produce a full range of models in collaboration with its upfitter partners.

“The VDRIVE™ is an all-electric skateboard architecture chassis and is basically a fully integrated chassis system with the drive system integrated, including the battery, motors, and controls – a fully functional platform that can be paired with various body configurations,” explains Fitzpatrick.

“VIA offers both complete vehicles – the cab with the upfitted body on the back – as well as the chassis cab, or skateboard only. Partners, upfitters, and manufacturers can use the chassis cab or skateboard with their own configuration, such as Pegasus Specialty Vehicles, incorporating the VTRUX® with their school bus architecture.”

Keeping pace in such a technological field, VIA operates an R&D facility in Utah, and boasts a headquarters and Tech Center in Auburn Hills, Michigan. It is facilities such as these that contribute heavily towards VIA’s overall mission – not just to be another truck-producing company, but to be a solutions provider for a sustainable future manufacturing functional, reliable, and durable electric work trucks that have an attractive total cost of ownership.

THE CORE OF VIA MOTORS

The VDRIVE™ skateboard is VIA’s key offering; the technology allows for a low load floor height and a driver-forward design, opening volume for the cargo area and making the experience better for drivers, with a tight turning radius and low step-in height.

VDRIVE™ is purpose-built from the ground up for a range of products and partners, and according to Fitzpatrick, is industry-leading in several ways – durable, robust, and capable skateboard architecture.

“It is also scalable in payload and battery capacity, and we cover Classes 2 to 5 with the intent to expand to Class 6,” she elaborates. “We go from 130 to 200-inch wheelbases with a ladder frame structure. The nature of our product design and how we manufacture it lands itself in a very low CapEx and a highly scalable product. We can build various products without incurring significant product development and capital tooling expenses.

“All vehicles are all-wheel drive (AWD) and cover battery capacities from 82 kWh (kilowatt hours) to 165 kWh. On top of this, we can pivot to different configurations based on the required payload and range.”

VIA’s skateboard is unique and compact, with a low load floor enabling less ergonomic stress for drivers to get in and out of a vehicle. Additionally, VIA’s ingenuity allows trucks to move more cargo and have a tighter turning circle than most of the company’s competitors.

“We’re not retrofitting internal combustion engine (ICE) chassis – not compromising in that way – but instead developing purpose-built architecture, giving the vehicle several fundamental attributes, and it all starts with the battery cell,” Fitzpatrick adds. “The real differentiator is the VIA product that is a result of passion and expertise.”Where the VDRIVE™ skateboard architecture is VIA’s core technology, VTRUX® is the vehicle platform that utilizes VDRIVE™ to flexibly design and build electric commercial vehicles of myriad sizes and models for various customer applications. It ranges from box trucks to shuttle buses, walk-in vans, and many more. A flexible, 100 percent electric work truck platform, VTRUX® allows customers to choose from a range of battery sizes and essential accessories. For example, refrigeration units or electronic lift gates, that provide tailored solutions at an attractive cost.