In the face of rapid change, many companies are seeking ways to remain at the forefront of the US aerospace industry. Lou Melluzzo, CEO of Air Industries Group, shares how his company continues to stay competitive, relevant, and successful.

FLYING HIGH

The US aerospace industry has witnessed considerable advancements in a short period, from the pioneering work of the Wright brothers to the inception of Boeing, alongside the development of state-of-the-art military aircraft, and the modern-day drone.

Air Industries Group (Air Industries), a manufacturer of precision assemblies and components for mission-critical aerospace and defense applications, seeks to stay abreast of a rapidly evolving aerospace industry.

“It’s a fast-paced sector, and a very exciting space to be in. The technology changes so quickly that you’ve got to stay on top of your game; it keeps you young,” opens Lou Melluzzo, CEO of Air Industries.

Melluzzo has been involved in the aerospace field since the mid-1980s when he studied as a design engineer. Driven by a passion for mechanical engineering, a creative imagination, and a desire to enhance and improve mechanics, he quickly climbed the ranks of several US engine component companies.

“I’ve always been a very critical thinker and I continuously strive to build a better tool. For as long as I can remember, my passion has been taking things apart and putting them back together, so the mechanical aspect of the aerospace industry is really attractive to me,” he reflects.

Headquartered in Long Island, and with manufacturing facilities in both New York and Connecticut, Air Industries is a small public company, occupying 200,000 square feet of manufacturing space. Much of the organization’s work is concentrated on military fixed wing landing gear and arresting gear, actuators, rotorcraft components, turbine engines cases, rotating engine seals, and submarine valves. The company is also licensed on aftermarket military spares programs, thus supporting out-of-production parts that the original equipment manufacturer (OEM) no longer makes.

The company views itself as not only a manufacturer, but as an integrator and assembly house. A one-stop shop for engineered aerospace components and assemblies. Air Industries seeks to provide a smooth, tailored customer experience.

“We favorably differentiate ourselves from other manufacturers by our ability to engineer, machine, and assemble from start to finish,” informs Melluzzo.

“It’s a fast-paced sector, and a very exciting space to be in. The technology changes so quickly that you’ve got to stay on top of your game”

Lou Melluzzo, CEO, Air Industries Group

STAND-OUT SERVICES

Since the onset of the COVID-19 pandemic in the US, supply chain operations across the country have been compromised from both a procurement and personnel standpoint. Notably, Air Industries has utilized this as an opportunity for growth.

Part of the company’s unique offering is a comprehensive in-house service, which mitigates the necessity for customers to outsource parts, labor, or supplies, and streamlines the entire experience.

“Customers don’t have to shop around to a dozen different places to achieve their goal. They can outsource their complete requirements to us, and we will integrate it, manage the supply chain, and oversee its total lifecycle,” Melluzzo enthuses.

Subsequently, many of the agreements and partnerships that Air Industries enters into are not stand-alone spot buys. Oftentimes, multi-year agreements are successfully arranged with clients, which Melluzzo attributes to a client-centric ethos.

“When we look at a partnership, we’re looking at what we can offer the client to make their life easier, and we see it as an opportunity to provide the total package. We tell them what it’s going to cost today, next year, and the year after that.

“We have a very dedicated and experienced team internally. We don’t just produce the component; we produce the entire finished assembly. That’s our first and foremost criterion,” he explains.

To facilitate Air Industries’ objective of self-sufficiency, the company has internalized several of its secondary operations.

“Most aerospace alloys require special processing. Heat treating, shot peening, non-destructive testing, chemical coatings, and painting are just a few common ones. Since COVID-19, we’ve started to integrate secondary operations into our facilities, like painting the parts in-house,” he exemplifies.

In addition, Air Industries is setting up a flash-welding department, to support some of its primary product lines. In the past, these processes were outsourced.

“Our plan is to insource a process or two each year, focusing on those that have historically impacted lead time, risk, or throughput. Managing what’s outside our walls is as critical as managing what’s inside,” Melluzzo reveals.

Furthermore, the company offers design integration services to every customer. This means expertly advising on potential design improvements or mechanical engineering queries.

“If a client is having a problem with a mechanical component in their fabrication, we can suggest how to design it differently to yield better results. We have that ability in-house,” explains Melluzzo.

“We have the ability, equipment, people, know-how, and engineering EXPERTISE to fabricate the whole assembly from start to finish”

Lou Melluzzo, CEO, Air Industries Group

EXCITING PROJECTS

Historically, Air Industries has been involved with a host of OEMs. Of note, the company’s work with the UH-60 Black Hawk helicopter (Black Hawk) over the past 40 years has made up a sizable chunk of its business.

“Approximately 25 percent of our business is conducted for or through Black Hawk,” Melluzzo states.

Air Industries has produced an array of structural components for the helicopter, whilst elements such as the main flight controls, throttle quadrants, mixers, and transmission mounts demonstrate the company’s mechanical versatility.

Black Hawk is one of the most successful US military aerospace programs of its time, with over 5,000 designated UH-60 units in the field. Some UH-60 models have expanded beyond military use.

“Many municipalities are now using the Black Hawk for a variety of applications. California, for example, has several operational helicopters to put out fires, as it’s such a reliable platform.”

Additionally, Air Industries has manufactured vibration dampeners for Black Hawk, specifically tuned to counter vibration transmission within the aircraft, along with push rods and tail cone assemblies.

“The Black Hawk program is near and dear to us. With around 5,000 helicopters in the field overall, the amount of spare parts required is incredible. We service this need through the OEM, and directly with the US government as required,” states Melluzzo.

Although fixed wing military jets are considered the bread and butter of Air Industries’ output and have always provided a stable foundation for steady growth, the company’s rotorcraft business has seen exponential growth of late.

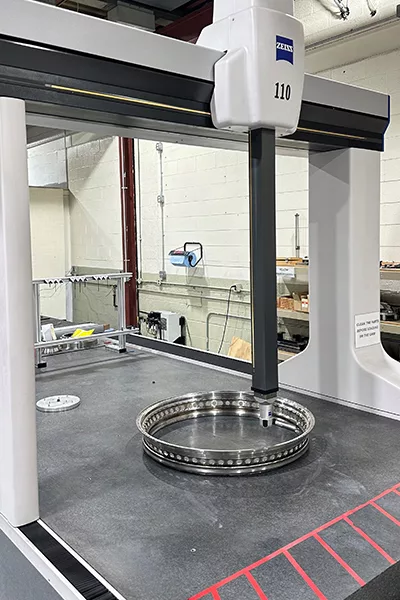

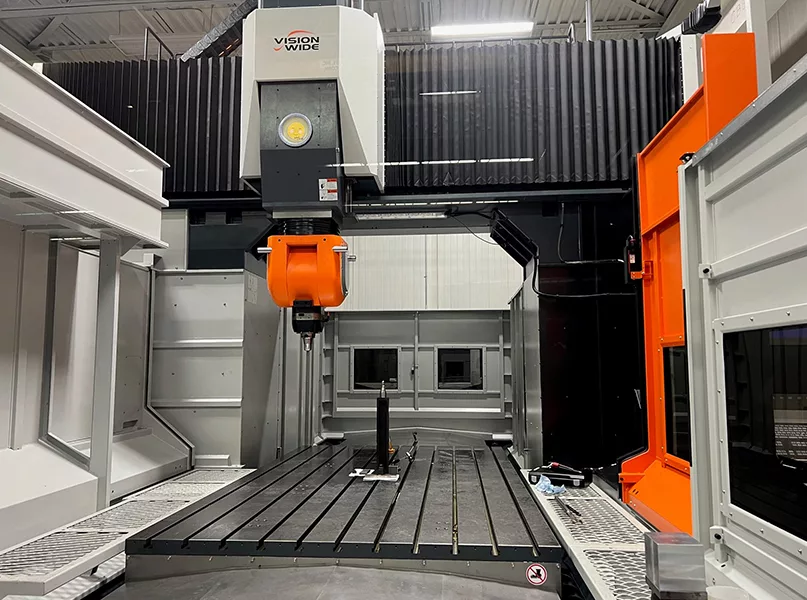

In the past two and a half years, Air Industries has invested nearly $12 million into new equipment to support the expansion of rotorcraft, whilst an expansion of the company’s Connecticut facility could see it spending another $15 million in the next several years.

“We’ve got the latest and the greatest machinery. We’ve increased the quantity and the overall size envelope of our five-axis milling and turning equipment, and increased the number of our state-of-the-art computer-aided design (CAD) seats (CATIA and Siemens NX). Given the cost and lead time associated with raw material, we simulate the complete manufacturing process before we ever cut a piece of metal. We don’t produce a part until we know that our processes and our computer-aided manufacturing (CAM) programs have been proven.

“It’s now a matter of creating the additional space and continuing to increase our staff in order to support the growth spurt we’re seeing,” informs Melluzzo.

POWERFUL PARTNERSHIPS

Over the years, Air Industries has developed a sturdy and reliable relationship with the US government. Due to the company’s comprehensive repertoire of military aviation parts, it has proven itself as a trusted supplier to the Department of Defense (DOD).

Through Source Approval Requests (SARs), which are used to demonstrate a company’s ability to manufacture a critical product, Air Industries proves its worth to the US government.

“What these packages prove, is that we can produce the part they’re looking to purchase either through prior experience with the same, or demonstrably similar items,” comments Melluzzo.

For a typical manufacturer, acquiring a direct government contract can prove very difficult to navigate due to the vast amounts of associated paperwork.

“This paperwork is almost as complex as the making of the parts themselves. We have an entire team dedicated to making sure that the paperwork is correct every step of the way. Smaller companies may not be willing to invest this time or manpower,” he shares.

In addition to its longstanding relationship with the US government, Air Industries has recently developed a partnership with a large European OEM following this year’s Paris Air Show.

Melluzzo is confident that Air Industries’ engagement with the European OEM will lead to a beneficial business relationship.

“We had a booth at the show, and were fortunate enough to have the right person stop by and ask the right questions. Within a very short period of time, this relationship started to mature,” excites Melluzzo.

This newfound partnership will not only extend Air Industries’ reach across the Atlantic and into the European aerospace market, but also contribute to increased commercial work.

“Just that one contact made the entire show worth attending,” he concludes.