Heading up the American transition to a low-carbon future, Lars Carlstrom, Founder and CEO of Statevolt and Italvolt, discusses one of the most impactful developments underway today – gigafactories.

As the US confronts the urgent need to tackle climate change and transition to a low-carbon future, the development of gigafactories – industrial plants which produce advanced lithium-ion batteries – has emerged as a pioneering solution. Gigafactories are state of the art facilities that have the potential to decarbonize crucial sectors of the economy where lithium-ion batteries can provide power. These sectors include transport, data centers, and renewable energy infrastructure.

The future success of decarbonization in the US will rest upon the ability of the country to dramatically cut the emissions from highly polluting sectors. A prime example is transport; the sector accounted for 29 percent of greenhouse gas (GHG) emissions in the US in 2021, significantly exceeding emissions from industry, which accounted for 23 percent. Producing lithium-ion batteries at scale will be crucial to support the decarbonization of the US economy. Furthermore, ensuring the US can meet its energy transition goals independently is essential to guarantee the security of supply and remain competitive on a global scale. Establishing a strong US footing in the battery production field will help counter China’s dominance in the electric vehicle (EV) supply chain and manufacturing process.

Gigafactories can lay the foundation for modern, future-proof industry in the US. As large-scale and technologically advanced battery plants, gigafactories have the potential to redefine the industrial landscape for states that build them. The highly complex and technological process for battery development requires specialist skills which can help attract talented workers to the facility’s location and help create opportunities for existing workers in the region – each factory can create thousands of highly-skilled jobs. This is especially true for gigafactories planned for development in the industrial heartlands of the Southern and Midwestern US, where workers possess deep existing knowledge in automotive or heavy industries, allowing them to upskill or develop entirely new capabilities.

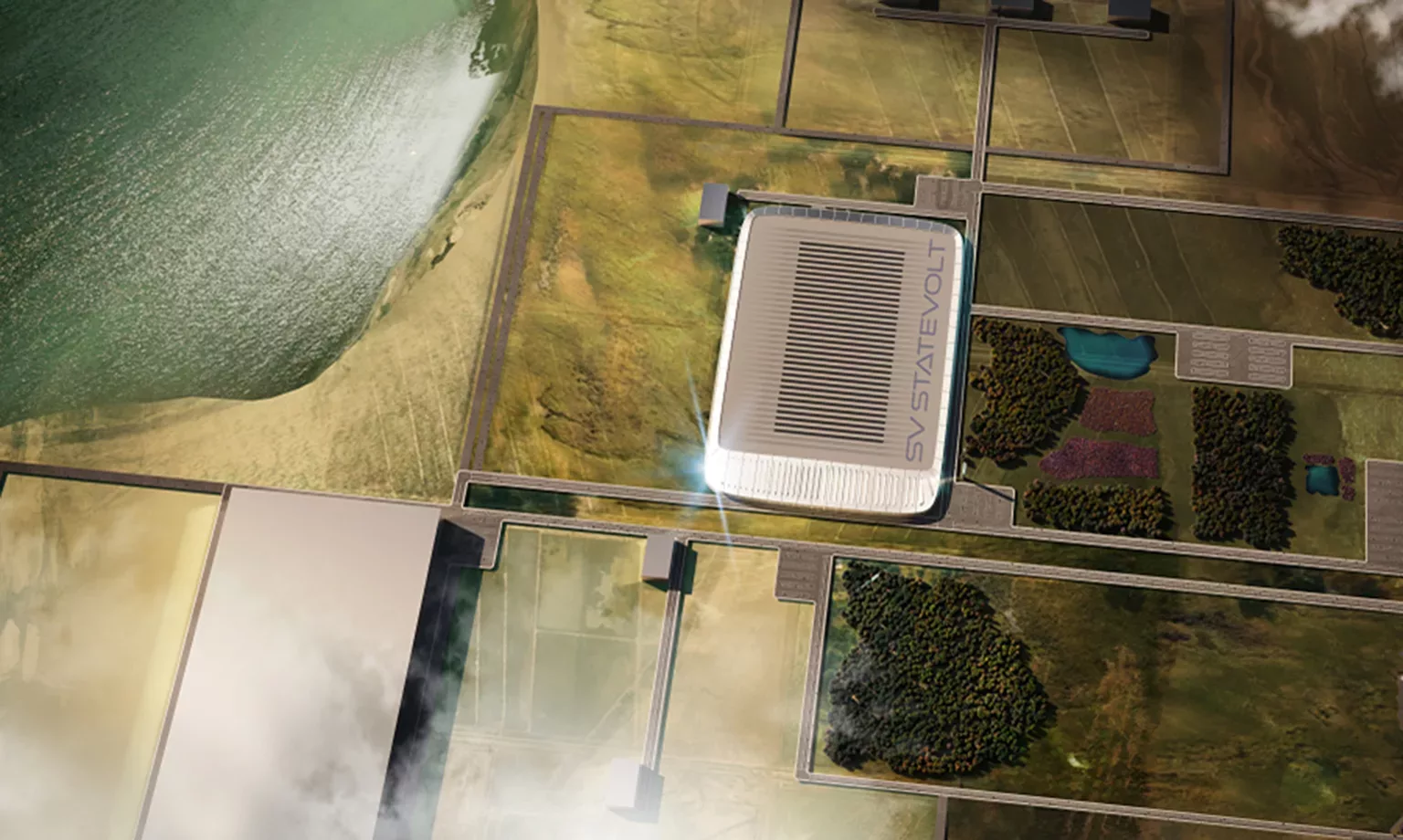

In addition to upskilling workers, gigafactory development can provide wider economic benefits in the communities where they are built. Statevolt, the company I founded and currently run as CEO, is building its gigafactory in Imperial Valley, California, and will serve to illustrate how gigafactories have the potential to revitalize underdeveloped communities. Due to their scale and highly advanced manufacturing processes, gigafactories can be economic engines that empower local communities and create high-quality jobs. Statevolt is focused on supporting growth and regeneration in the area, with an ambition to provide direct employment for up to 2,500 people in the Imperial Valley community.

To further reduce carbon emissions from gigafactory and lithium-ion battery development, Statevolt is pioneering a ‘hyperlocal business model’, which aims to rely on local sourcing, processing, and production to produce lithium-ion battery cells that are made in the US from start to finish. The result will be a local and reliable supply chain that eliminates dependence on foreign sources while reducing the net carbon footprint.

Given the level of capital required to start a gigafactory, each project represents a huge investment in the region. GlobalData research estimates that between $106 billion and $177.6 billion is set to be invested in gigafactories worldwide between 2020 and 2030. Gigafactories can provide significant direct and indirect economic opportunities for local communities, as well as adjacent industries which supply gigafactories and the needs of their employees. The gigafactory Statevolt is currently developing aims to create 2,500 full time jobs for people in the Imperial Valley region.

The plan to build gigafactories across the US will not be without its challenges, notwithstanding the large capital expenditure required to kickstart production. However, as the demand for EVs and energy storage rises over the coming decades, there is a strong imperative to accelerate gigafactory development. States such as California have implemented bans on the sale of new petrol and diesel cars from 2035, as a means of accelerating the switch towards battery powered EVs by 2035. As such, lithium-ion powered EVs are the only realistic alternative.

According to the International Energy Agency’s (IEA) Sustainable Development Scenario, for the world to meet climate and sustainable energy goals, close to 10,000 gigawatt hours (GWh) of batteries and other forms of energy storage will be required worldwide by 2040, which is around 50 times the size of the current market. For us to meet net zero targets while securing a just transition, we must look towards gigafactories as the solution.

The development of gigafactories across the US will make the shift to net zero a sustainable and efficient reality while strengthening the US’ automotive industry.

A hyper-local business model which narrows the distance between producers and consumers can further advance these aims, creating a positive, long-term economic future for people and economies throughout the continent.