With an esteemed heritage dating back to the Golden Age of Space Travel, we speak to Patrick Marotta, the third-generation leader of historic family-owned aerospace and defense manufacturer, Marotta Controls.

INTRODUCTION

Speed, agility, innovation.

For Patrick Marotta, the third-generation leader of Marotta Controls, it is these three tenets that best define the historic New Jersey enterprise as it stands today. Accompanying these foundational principles, is an overarching concern for the customer that transpires to every level of the business.

As a fully integrated solutions provider to design, develop, qualify and manufacture innovative systems and sub-systems for the aerospace and defense sectors, Marotta Controls was founded in 1943 as a small, family-owned business, initiated by Patrick Marotta’s grandfather, that went on to earn an iconic legacy.

Perhaps most significantly, Marotta Controls is renowned as the manufacturer to have supplied the valve systems for the Saturn Apollo mission landing a man on the moon.

“Marotta started as a valve company. My grandfather had a chance meeting with an engineer at Reaction Motors who was looking to solve how to get a fuel and oxidizer to the motor for the Bell X-1 – the company was only two years old. He had an idea that led to developing a balanced poppet solenoid valve and that is still part of our mainstay product line today. It is significantly evolved, but it still looks the same from the outside.”

Today, the company boasts a portfolio spanning pressure, power, motion, fluid, and electronic controls for weapon systems, shipboard and sub-sea applications, satellites, launch vehicles, and aircraft systems.

“Our growth and profitability are an outgrowth of how we support the customer and our willingness to lean in and do things for them, sometimes in advance of receiving a contract. That is what makes us different and it’s something that I don’t see changing. That is part of our hard DNA”

Patrick Marotta, President and CEO, Marotta Controls

EMBRACING AGILITY – FROM APOLLO ONWARDS

Since the company’s nascency over 70 years ago, agility has been woven into the fabric of the company but was truly brought to the fore when the present CEO, Patrick Marotta took the helm.

“Each of our decades saw a consistent rotation through our primary customers – first space, then marine, then nuclear, then back to space, and so on.

“When I entered the business, I wanted to end that cycle and move all areas forward in unison, even if they weren’t going to grow at the same rate. I wanted them all to have a piece of our time and attention,” Marotta states.

Aside from this, Marotta sought to diversify and extend the product line in order to guarantee business continuity and sustainable revenue.

“We went through almost a decade of production where 50 percent of our revenue came from the International Space Station and then when it was over, it was over.

“We didn’t want to move away from our heritage of custom solutions but we needed to strike more of a balance between engineering a product that can be sold and generate recurring revenue and those custom solutions,” he explains.

Although still operating out of the original facility purchased by the late Pat Marotta, the site has evolved to keep pace with the forefront of industry innovation and catering to a diversified portfolio offering.

“We are still in the same location that my grandfather purchased when my grandmother kicked him out of the basement,” he quips.

Now, as the company approaches 500 employees – 130 of which are employed in engineering roles – physical expansion is on the agenda with a new Support and Engineering Center set to open later this year, enabling the primary facility to be dedicated solely to Production.

A significant decade for the company, it was during the 1960s that Marotta Controls introduced its first closed-loop pneumatic control system – something which continues to be a prominent factor for the company today.

“One of the things that’s very unique in terms of Marotta’s facility and the way that we have developed and grown it, is the high-pressure pneumatic testing capability.

“Five years ago, when we did our last expansion on the building, we refreshed an entire high-pressure pneumatic system that was developed and put in the 1960s in support of Saturn and Apollo. Now, it is state of the art, it is 7,500 PSI of nitrogen, we have 15,000 PSI capability, we can run long duration flow tests, and that’s just on the refresh of the pneumatic side,” he explains.

“On the electronics side, we are able to take on and develop high-power conversion systems for modern aircraft and missile systems.”

Innovation is at the crux of agility, enabling Marotta Controls to take legacy products and update them to keep pace with a higher volume and demand in a transformed industry.

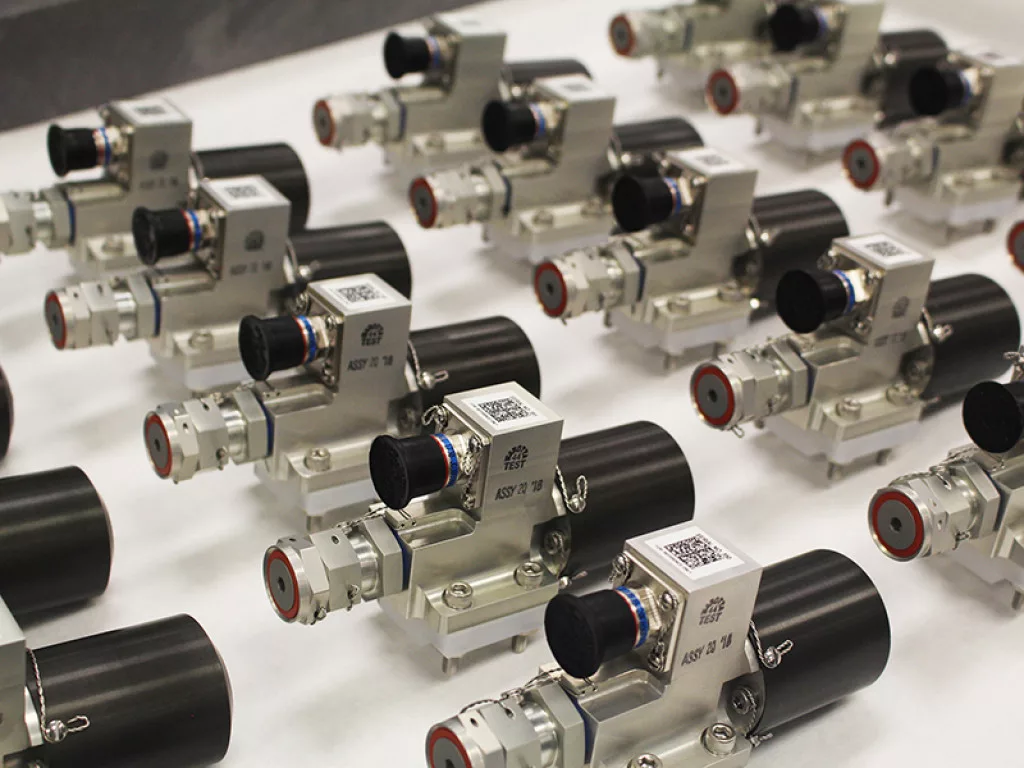

“The way that space launch happens today, it’s much more aggressive, not just on pricing but on capabilities and all the specifications. They are looking for the same or better performance of a legacy product, but that product was never designed to be put together in the 100s per month, which is what we are doing today,” Marotta explains.

Marotta Control’s prowess in this area is best evidenced by their ongoing partnership with major commercial space companies that the former president decided to take a chance on by supplying them with several valves free of charge, during the companies’ infancy. Marotta now identifies that exchange as paving the way for a new wave of engineering partnerships across the industry.

“Marotta is not afraid to embrace the not-invented-here solutions that are shunned by a lot of designers. We will never automatically dismiss it before investigating if that is the right solution”

Patrick Marotta, President and CEO, Marotta Controls

CUSTOMER FIRST

Embodying the unison between a customer centric approach and agility is the recent restructuring of the Marotta Controls enterprise into separate business units, driving further dedication and concentrated individual attention in the face of a growing company.

“Now that we’re well over 400 people, the organization started to lose a bit of that intimacy with the customer,” he comments. With sheer volume and scale limiting the amount of customer visits and business, the company was split into four business units, comprising aerospace, space, marine and tactical systems.

“By driving the customer intimacy to that lower level, we can have a group of maybe 100 people who are just dedicated to making them successful and are very familiar with what’s going on with their subset of customers,” Marotta explains. Since trialling this new way of working with the space segment as the first business unit, Marotta Controls has witnessed the successes of each unit thriving and approaching their individual segments in a unique way.

The cornerstone of Marotta Control’s success relies on its staff, each individual cog in the overall machine bringing a strong sense of play and creativity to their role.

Marotta focuses heavily on feeding the creativity of their engineers and is extremely responsive to identifying and nurturing good ideas.

“We had one engineer who was working on a program that ended, and he said, ‘no I still have this idea and want to make something of it’. He quickly showed us the novelty of his concept and we supported him and put a team around him and now that idea is the foundation of many of our power conversion product offerings,” he tells us.

The aforementioned product pertains to Marotta’s ‘1-STEP’ technology – an innovative circuit solution that has effectively revolutionized power conversion.

For Marotta, the motivation and empowerment behind his workforce all ties back in to those three foundational concepts that propel the business forward – speed, agility, and innovation – all of which also serve as a “tremendous positive” for the customers of Marotta Controls.

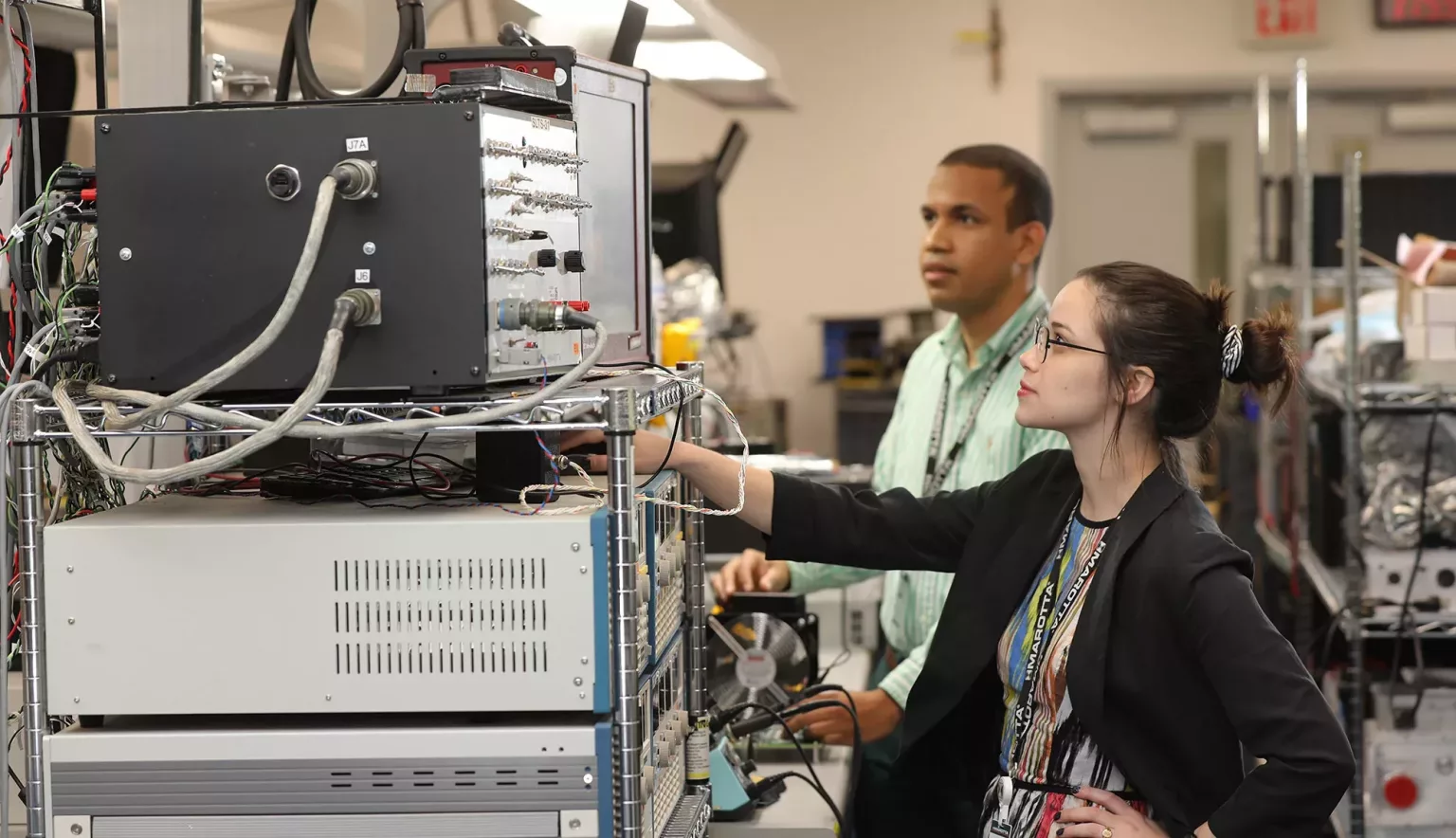

“These are also the top three things that we can offer to new employees,” Marotta tells us. “Within a very short period of time, new employees will be making a tangible difference in how a customer is supported.

“We get our employees, new, experienced or otherwise, in front of customers and paired up with seasoned engineers or development technicians, right away. We don’t take ourselves overly seriously, but we are creative, we work with what we have. We know our customer’s needs,” he adds.

Marotta Controls prides itself on its individual relationships with customers and its true dedication to first identifying the problem and pursuing the most cost-effective and efficient solution on their behalf.

In order to do so, a robust and reliable supply chain is crucial. This is a network that has evolved significantly within the past twenty years of Marotta Control’s journey, when previously 80 percent of Marotta Control’s products were made in house. Evolution ensued, whereby supply chain developed to form real partnerships, allowing the company to accommodate a modern machining facility whilst also investing in new technologies.

“We rely on them to give valuable feedback on how we are doing designs, because we never had that insight, we had always been very insular in our own way of thinking.”

EYES ON THE HORIZON

Looking to the future, it is this focus on staff that remains essential.

“Our number one priority is recruiting. We have been very fortunate in both winning new contracts and opportunities proposing creative solutions that have gotten a lot of traction with our customers and we just need more hands to do more work.

“New Jersey’s been very good to us in terms of new talent, especially the talent that is originally from New Jersey – but we need to continue to recruit the best talent that we can, in both manufacturing, production engineering and design engineering,” Marotta surmises.

Leading with agility and a customer centric focus, Marotta attributes the company’s heritage as a truly competitive advantage to secure its continued success, enabling an unparalleled long-term view on investments.

Marotta himself hints to the promising development of a pet project within alternate actuation that will supersede the traditional magnetic coil solenoid.

“I think that a more energy efficient lighter weight actuator is around the corner, we will definitely be working on that.”

Aside from this, Marotta Controls will continue to focus on incorporating best practices whilst faced with unprecedented high rates of production within aerospace, as its esteemed legacy continues to evolve.