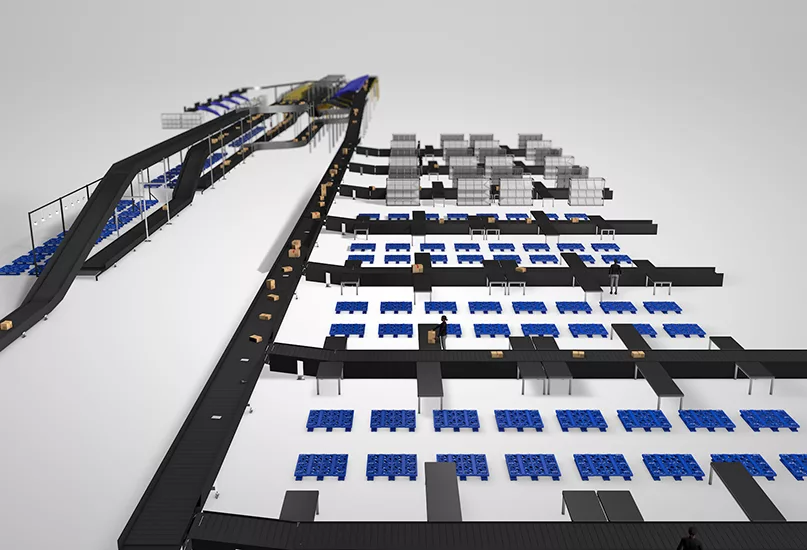

Designed Conveyor Systems continues to deliver unique, customized material handling solutions and fulfillment automation that leverages the latest technology and equipment. We find out more with Seth Taylor, Executive Vice President of Operations.

SUPPLYING SUPERIOR SOLUTIONS

Designed Conveyor Systems (DCS) has expertly garnered 40 years of experience serving major clients in multiple industries by providing material handling, full-scale warehouse operations, and conveyor design solutions that are custom-crafted for their needs.

The company does not sell ready-made conveyor systems, but instead builds relationships that empower the collaboration to craft custom warehouse designs. Furthermore, DCS utilizes consulting, engineering design, project management, installation services, and client support to ensure its customers can keep their promises to deliver on time.

Founded in 1982, DCS now draws on a plethora of experience in the supply chain industry, serving its customers in the e-commerce and multi-channel fulfillment segments as well as the parcel handling and transportation arenas.

“We provide a full breadth of services, including network and operational consulting, systems design solutions, material handling equipment (MHE) engineering, integration services, 24/7 support, and full-scale warehouse operations,” introduces Seth Taylor, Executive Vice President of Operations at DCS.

“We grew from a small shop in Franklin, Tennessee, into a nationwide leader in the industry. While our headquarters has always been located in Franklin, we have expanded to host over 300 employees in every region of the country,” he enthuses.

Taylor leads his team with nearly 25 years of experience in the material handling industry and oversees the entire operations team of DCS, which includes all project delivery and support efforts.

MAINTAINING ORGANIC GROWTH

During the last five years, DCS has prioritized organic growth within its established client base.

Despite achieving impressive year-over-year revenue increases of over 50 percent, the company recognized that maintaining this expansion rate was unsustainable and contrary to its principle of responsible growth.

“The ongoing pressure on our internal resources was also becoming untenable. Consequently, we shifted our focus to external expansion strategies,” recalls Taylor.

In 2021, DCS pinpointed two key areas for growth that resonated with its specific values and expertise: mergers and acquisitions (M&As), and product development.

“Our venture into M&As began a little over a year ago, stemming from what was initially a simple networking call with a former subcontractor partner. This interaction unexpectedly evolved into an excellent opportunity to merge two compatible companies,” he continues.

In March 2023, DCS successfully acquired IMI Industrial, a move that significantly enhanced its service capabilities to a crucial customer and marked a new chapter in the company’s history. This acquisition not only served as a horizontal integration within the supply chain, but also opened doors for vertical integration, a prospect DCS plans to pursue further.

Moving forward, another strategic focus is product development, driven by clients’ need for more than just a standard MHE integrator. Recognizing a demand for a next-generation software platform, DCS has developed Datum, a toolset offering robust integration middleware that is original equipment manufacturer (OEM) agnostic.

“This development prevents our clients from being limited by proprietary systems and addresses a significant gap in the business software market.”

Datum was built on three core principles, the first of which is to address client problems directly, ensuring that the software is designed from the ground up with client needs in mind.

Second, DCS emphasized the openness of data and algorithms, ensuring its standards are collaborative and integrate seamlessly with existing client enterprise tools.

Lastly, the company is committed to delivering optimized software solutions without high risk or cost, prioritizing quality over speed in the development process.

Seth Taylor, Executive Vice President of Operations, Designed Conveyor Systems

“We are among the few remaining true design-build systems integrators, boasting the capability to handle a wide range of projects while maintaining a close, familial relationship with our clients”

INTEGRATION AND ADAPTATION

Over the past decade, the vast supply chain industry has undergone significant consolidation, merging multiple integrators, manufacturers, software companies, and service providers.

This dynamic shift has led to what Taylor refers to as the “disappearance of the project middle-class.”

After this extensive merging, only a few large companies and numerous small, family-owned businesses remain. Therefore, in this landscape, DCS stands out as a unique entity.

“We are among the few remaining true design-build systems integrators, boasting the capability to handle a wide range of projects while maintaining a close, familial relationship with our clients,” he shares.

Furthermore, as a true integrator, DCS is committed to unbiased decision-making when providing solutions to customers.

“We aren’t tied to promoting specific technologies within a corporate portfolio, allowing us to deliver high-value, cost-effective solutions without the constraint of filling internal resource quotas.”

Interestingly, aside from its talented team, DCS holds few physical assets. This raises the question of how a true integrator keeps its customers satisfied.

The answer lies in DCS’ strong relationships with partners and suppliers.

To nurture these crucial relationships, DCS has established a dedicated supplier development team with the sole purpose of maintaining and enhancing its supplier partnerships. Their role involves a delicate balance of seeking value, ensuring fairness, distributing work evenly, and forging new connections, while continuously engaging in communication.

Elsewhere, the team’s responsibility extends to understanding the capacities and capabilities of DCS’ suppliers and acting as an internal consultant to align these resources with business and project needs.

This specialist unit plays a crucial role in addressing any project-related concerns and offering guidance and constructive feedback to suppliers. This approach also means that DCS doesn’t always opt for the most immediately profitable decisions.

“Instead, we are committed to a strategy of long-term success and sustainability,” Taylor assures.

“To provide the best-in-industry experience to our teams, we have chosen to be a culture-forward company”

Seth Taylor, Executive Vice President of Operations, Designed Conveyor Systems

A CULTURE-FORWARD COMPANY

DCS’ overarching company mission is to deliver the best customer and employee experience in the industry.

“To provide the best-in-industry experience to our teams, we have chosen to be a culture-forward company. When we ask our employees why they choose to work at DCS – and we know they have a lot of choices – the overwhelming answer is the culture,” shares Taylor.

In this way, culture is at the core of all DCS’ discussions, decisions, and engagements. The positive and welcoming working environment is a key differentiator for the company in the marketplace.

“During our 2023 Leadership Conference in November last year, we had Echelon Front, a top leadership consulting company, come in and provide an entire day of training under the topic of extreme ownership.”

The themes of empowerment and autonomy in the workplace rose to the top of discussion points and provided an enlightening understanding of all sides’ views of autonomy and how to ensure growth for the entire company and its people.

Furthermore, the DCS executive leadership team considers the autonomy of its employees and teams to be critically important to the success of the company, as it believes that trust is the key.

Employees must feel trusted by leadership and know they are empowered to make decisions. The other side of that trust comes from the team members thinking critically and taking ownership of those decisions.

“Autonomy allows us to grow both the people and the organization,” he finishes.

Moving into a bright future for the company, DCS is continuing to expand through three specific lenses – diversification, product creation, and M&As. These categories, along with the maintenance and expansion of its culture, are at the top of a list of priorities for the coming year.